Alternative energy sources have become a hot topic in recent years. The supply of fossil fuel, which provides ~ 80%ercent of total energy demand today, will eventually run out in a few decades. Germany, which has the largest installed base of solar and the third largest installed base of wind gets more renewable energy from organic materials than wind and solar combined. Indeed, in 2010 it had approximately 6,000 biogas facilities generating 2,300 MW of electricity, providing power for approximately 4.3 million households (German Biogas Association). In short, Germany serves as a model of a bioenergy economy that produces energy, creates skilled jobs, improves energy independence and stimulates economic growth (BMU).

Biomass gasification, with its capability to work in kW scales (as low as 20 kW) and its ability to utilize a wide and diverse range of biomass feedstock (including agriculture and crop waste) is ideally suited for the power needs of many segments. This ideally suits rural areas where access to power is minimal but an easy access to significant amount of cheap (and many times no cost) biomass is prevalent.

As per Study report by Energy Alternatives India (EAI) with over 60,000 villages not connected to the grid, the use of distributed renewable power sources is the need of the hour for India; among the renewable power sources, biomass could play an important role owing to its easy availability in rural areas, and biomass gasification an even more important role owing to its ability to operate at very low scales. As per study by EAI biomass gasification based power production in India could grow from about 80 MW currently to over 500 by 2015

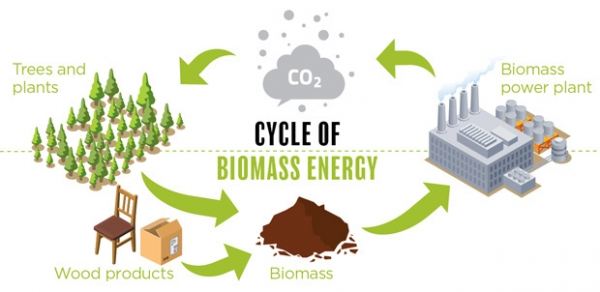

By contrast, biomass and biofuel have the potential to become one of the major global primary energy sources along with other alternate energy sources in the years to come. A wide variety of biomass conversion options with different performance characteristics exists.

Among the biomass power production routes, combustion and gasification are the two primary routes being used today. Biomass gasification works well for small scale power production, up to a maximum capacity of 2 MW. Combustion, on the other hand, works well at 5+ MW scales. As a result, biomass gasification could be one of the most appropriate technologies for biomass-based small scale power.

Alternative energy sources have become a hot topic in recent years. The supply of fossil fuel, which provides ~ 80%ercent of total energy demand today, will eventually run out in a few decades. Germany, which has the largest installed base of solar and the third largest installed base of wind gets more renewable energy from organic materials than wind and solar combined. Indeed, in 2010 it had approximately 6,000 biogas facilities generating 2,300 MW of electricity, providing power for approximately 4.3 million households (German Biogas Association). In short, Germany serves as a model of a bioenergy economy that produces energy, creates skilled jobs, improves energy independence and stimulates economic growth (BMU).

Biomass gasification, with its capability to work in kW scales (as low as 20 kW) and its ability to utilize a wide and diverse range of biomass feedstock (including agriculture and crop waste) is ideally suited for the power needs of many segments. This ideally suits rural areas where access to power is minimal but an easy access to significant amount of cheap (and many times no cost) biomass is prevalent.

As per Study report by Energy Alternatives India (EAI) with over 60,000 villages not connected to the grid, the use of distributed renewable power sources is the need of the hour for India; among the renewable power sources, biomass could play an important role owing to its easy availability in rural areas, and biomass gasification an even more important role owing to its ability to operate at very low scales. As per study by EAI biomass gasification based power production in India could grow from about 80 MW currently to over 500 by 2015

By contrast, biomass and biofuel have the potential to become one of the major global primary energy sources along with other alternate energy sources in the years to come. A wide variety of biomass conversion options with different performance characteristics exists.

Among the biomass power production routes, combustion and gasification are the two primary routes being used today. Biomass gasification works well for small scale power production, up to a maximum capacity of 2 MW. Combustion, on the other hand, works well at 5+ MW scales. As a result, biomass gasification could be one of the most appropriate technologies for biomass-based small scale power.

The gasifier is the key component in a biomass gasification system. The most commonly used gasifier in India is the downdraft gasifier, which is more suited than others for biomass gasification.

A wide variety of feedstocks can be used in the biomass gasifiers, and India is endowed with significant quantities of these feedstocks. Some of the prominent biomass used are rice husk, rice straw, coconut shells, cotton husk, bamboo etc.

The key market segments in India for biomass gasification are the small/medium industries, commercial sector and rural communities.

We'd Love to Hear From You